Lightness, strength, recyclability, local production... the use of composite materials is a key concern for most of the world's major industrial groups. So important is this sector that it even has its own European Composites Days, the JEC World in Paris. Among the 27 companies making up the Belgian delegation presenting their innovations, we met up with Sobelcomp, a Walloon company specializing in the creation, development and production of sustainable composite materials. What are the challenges facing the sector? What are the advantages of Belgian know-how? We've just had a nice chat with John-Thomas Thaels, Managing Director at Sobelcomp.

Belgium's rich history of innovation extends to the composites ecosystem, where a culture of research and innovation has led to the existence of dynamic, competitive industrial clusters. European collaborative projects involving industry players and research institutions (Cobracomp...) focus on advancing sustainable composite materials, manufacturing processes and end-of-life solutions. As a country with a large number of small and medium-sized enterprises (SMEs), Belgium's flexibility and commitment to cutting-edge technologies place it de facto at the center of pan-European exchanges and production systems.

As the country of honor for the 2024 edition of JEC World, the world's largest trade show dedicated to composite materials, Belgium, represented by Agoria, Skywin, Mecatech, etc., will be confirming its central position as an innovative force in the composites industry, and will be on the doorstep of industrial groups looking for partners offering tailor-made, sustainable solutions for their industrial development.

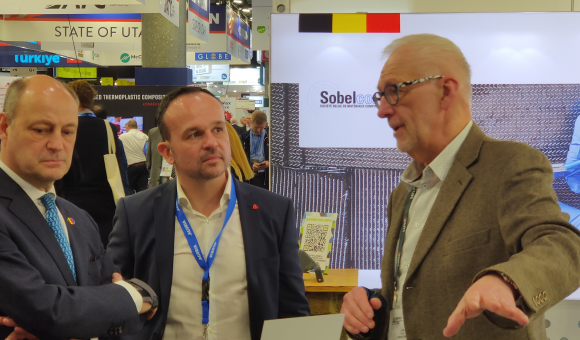

It was on the 'Belgium' stand that we met the team from Sobelcomp, a company specializing in the design, development and production of composite materials for the aerospace, automotive and energy industries. It was a great opportunity to talk to this specialist about the challenges facing a sector that is being courted from all sides to meet industrial and environmental challenges.

Wallonia.be : Hello. Thank you for your warm welcome. Could you introduce us to Sobelcomp?

John-Thomas Thaels (JTT), Managing Director at Sobelcomp: Hi. So, Sobelcomp was founded in 2005 to respond to the industrial problems of our companies through the use of composite materials (mass, size, strength, etc.) such as carbon fiber and epoxy resin. Today, we are a team of 45 people spread over two production sites near Liège and Charleroi. In concrete terms, we support our customers in the development of their composite materials projects, from computer-aided design to finishing, manufacturing, robotized machining and assembly of high value-added products.

Wallonia.be : In which sectors is Sobelcomp specialized in?

JTT: Mainly aerospace, defense and construction. The products we develop have the advantage of being lightweight, exceptionally resistant to corrosion and rigid enough to reduce the structural bending induced by their use. You can imagine that these qualities are highly sought-after by aircraft manufacturers, for example. In industry and construction, we are also working on materials that offer additional insulating or heat-reducing qualities. Given the stringent requirements of the ASD (aerospace-defense) sector, our products are all EN 9100 and ISO 9001 certified. In a nutshell, these are the main advantages of the products we develop for our customers.

Wallonia.be: The composites sector is all about innovation. What will be the material of the future?

JTT: It's funny you should ask that, because composites is a sector that is both recent and full of promise, and at the same time very old. Since time immemorial, man has been keen to assemble materials to improve his condition, whether in construction, clothing... Did you know that composite materials are even found in their natural state, having been used since prehistoric times?

Wallonia.be : Which one?

JTT: Wood. In the final analysis, this material is an assembly of resin and plant fiber. Wood itself is an assembly of these materials. But to come back to our discussion, yes, it's a sector with a future. The industry is well aware that we live in a world of finite, limited resources, and that we absolutely must develop alternatives to conventional materials if we are to continue to develop without compromising the state of our environment and our natural resources.

Wallonia.be : So the material(s) of the future will be the one(s) that meet this 'technology' and 'environment' equation?

JTT: Yes. Today, manufacturers are looking for lightweight, strong composites that save weight and space, so they can move goods using less energy. Carbon fiber aircraft are without doubt the best example of this.

Wallonia.be : Who are your customers? Where are your products exported?

JTT: Of course, they come from the sectors I've just mentioned. We work, for example, with Airbus, Safran, Prayon... Our industrial partners are mainly based in Belgium, but they export a lot. Around 95% of the products we produce are sent abroad, via our customers, to the four corners of the globe. So we cover a good part of Belgium, and we're now expanding into the rest of Europe.

‘Designed’ and… ‘made’ in Belgium

Sobelcomp is part of a rich ecosystem of companies and research centers, some of them university-based, capable of responding rapidly to the R&D needs of most of the world's major industrial groups. As a strategic hub, Belgium, which includes Wallonia, stands out as a center of innovation in composites, thanks to renowned universities such as the University of Liège, the University of Mons and the University of Louvain, as well as specialized technical institutions such as Cenaero, the Liège Space Center, Materia Nova and Sirris.

These university and research centers not only contribute to cutting-edge developments in the field of composites, but also have long-standing expertise in sustainability (renewable energies) and are involved in European recycling projects concerning wind turbine blades and release adhesives: exploration of sustainable alternative resins and fibers, digitization and automation of production processes, design of lightweight products for additive manufacturing sub-sectors (hydrogen tanks...).

At JEC World, Agoria, the Belgian federation of technology companies, pointed out that the Belgian composites ecosystem in Wallonia plays a key role in the automotive and transport industries, meeting the demand for lightweight materials for electric mobility to improve fuel efficiency and reduce emissions. In addition, the country's commitment to renewable energies is fuelling demand for composites in wind and solar power projects, taking advantage of their anti-corrosion and low-maintenance properties.