Walloon company Reprocover is one of the only companies in the world to recycle thermoset materials to give them a second life. Based in Verviers, the factory of Reprocover is in charge of the entire process, from waste collection to new products creation, playing a key role in the circular economy.

Reprocover was born out of a desire to recycle thermosetting composites. “At the time, most of of these composites ware piled up in garbage dumps or converted into energy”, explains Charles Göbbels, CEO of Reprocover. The company from Verviers wanted to go one step further by giving a second life to this unexploited waste and focusing on circular economy.

Recycling is part of the Göbbels family’s history, already active in the market of recycling of unvulcanised rubber. In 2017, it acquired Reprocover. Charles Göbbels now runs the company, while his father is at the head of Simonis, a sister company located a stone’s throw from Reprocover. “We often work together.”

An innovative transformation process

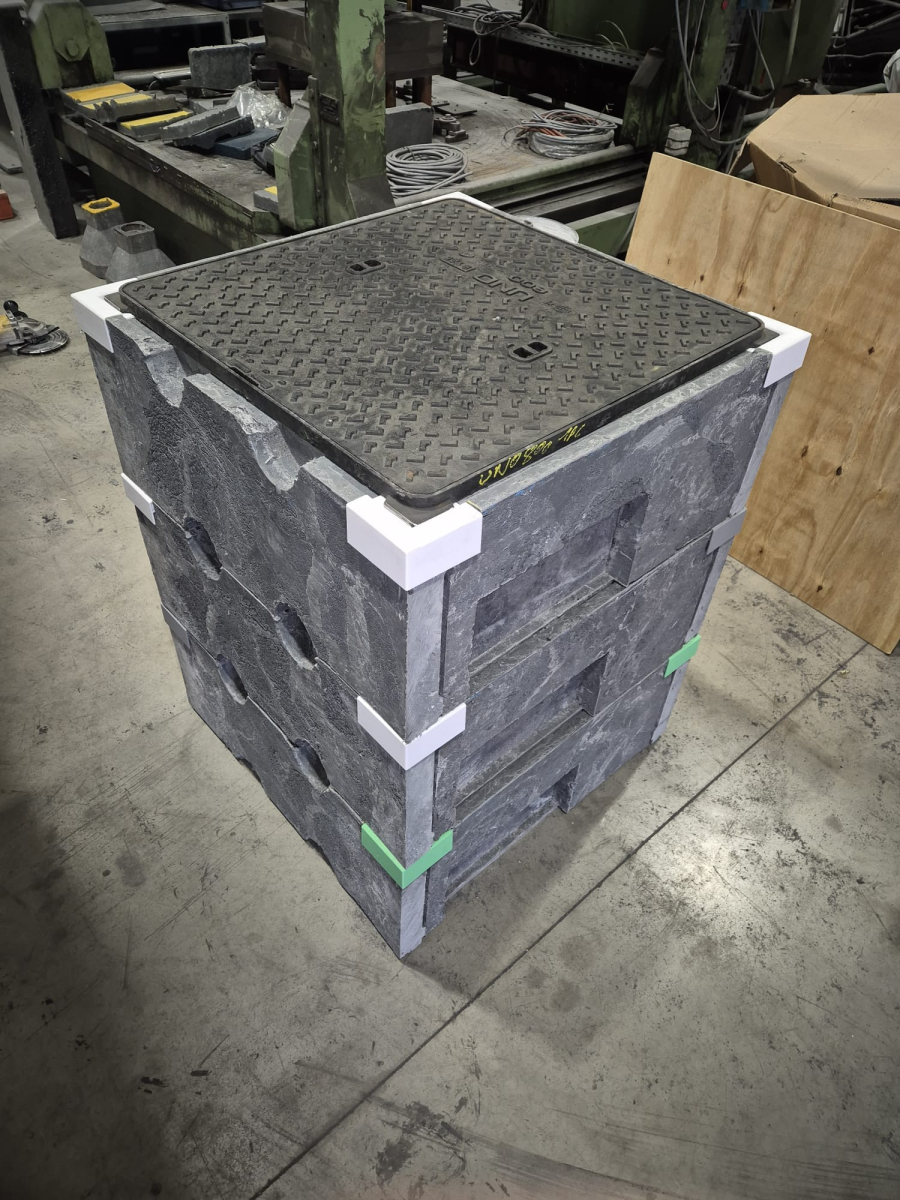

On the site, mountains of waste from windmills or electric equipment are stored outside. Indeed, companies pay Reprocover to recycle their waste. It collects it, granulates it so that it can be reused in new products or returned in a new form. Then, Reprocover characterizes its mechanic properties and transforms it into a brand new product: gutters, pedestrian and road crossings, inspection chambers for water, gas and telecommunications. And even custom products, the creative possibilities are endless. In only ten minutes, a piece of waste can be transformed.

In 2019, Reprocover launched the Pitras project with the Walloon Region. It improved the quality of recycled products and increase the diversity of raw materials used. In 2021, the Ad-corssi project subsidized by the Walloon Region began to automate the quality and sustainability of the manufacturing and recycling process. In 2023, a new federal project started to prepare recycled materials for other companies. “We have lots of ideas for development, but the costs are still high. For now, our factory covers a radius of 600km, but we would like to duplicate it to reach 1,200km. We’re thinking of opening a second branch in northern Germany, Poland or southern France.” Before setting up abroad, Reprocover must first create demand even though “95 % of its products are exported internationally”. The company is also considering working with Norway.

Reprocover, the reference of thermoset recycling

Ecology is at the heart of Reprocover. “To measure our environmental impact, we work with the University of Liege to do our life cycle assessment (LCA) of our raw materials and our products. It enables us to compare our carbon impact and to optimize our processes to reduce it as much as possible. We have to both respect our customers’ demands and adapt to balance the cost/ecology.” To encourage other companies to follow the zero-waste journey, Reprocover carries out lobbying projects. It informs them about legislative changes and helps them integrate more recycled materials into their production. It also tries to get them to include LCA in their specifications.

In the long term, Reprocover wants to remain the reference entity in thermoset composite recycling, but the road ahead is full of pitfalls. They have to track waste and standards are constantly increasing. Moreover, today everyone is trying to sell its products as the most sustainable. That’s why European Union has introduced legislation to measure LCA. In 3 to 5 years, it will be possible to observe Reprocover’s real impact on society. In the meantime, some sectors such as the automotive industry are already moving. Cars must contain at least 30 % recycled materials and manufacturers are turning to companies like Reprocover.

Charles Göbbels, whose company has recycled between 3,000 and 4,000 tonnes of waste since 2018, concludes with an advice: “Never lose hope. You need to be strong enough to keep going, and above all, find the right people to make things happen. Networking is also a key factor in finding solutions.”

Julie Hanssen (AWEX)